Crash of LN-20 - 1969

By: Bill Hobgood and Robert Hartl (Robert was aboard LN-20 this day!)

Author’s Note: This “Sea Story,” about the 1969 mishap that occurred in Adak, was originally penned by Robert Hartl. After conversing with Robert and Randy Hotten (the copilot who made the takeoff that day) I decided to make it a “Special Report” article for the September 2015 Pelican Post Newsletter.

I have taken, and am grateful for, the recollections of Bob Hartl and Randy Hotten (both first tour pilots) along with other research

data to come up with this story. I have also included some minor fabrication and employed literary license, to provide background,

fill in missing data or connect recollections, that may be in error or not completely factual. For that I apologize in advance.

Also, If you would prefer to read this article/Sea Story in the Newsletter (which has a number of photos), Click Here and go to page 16.

The weather was clear on June 1st of 1969 but there was a substantial crosswind as the P-3A (BUNO 151363) approached the runway at NAF Adak, Alaska. Both pilots noted the lack of surrounding vegetation and color; the entire base seemed to be white, brown and shades of gray. Early summer outside air temp was a nippy 45 degrees. This environment would be new to the crew aboard LN-20 as VP-45 was a Jacksonville based squadron and had just completed six months deployed to the sweltering hot Sangley Point naval air station, located on that spit of land jutting into Manila Bay, Republic of Philippines.

In 1969, the conflict in Vietnam continued to rage. For a period of time, even the East Coast based P-3 squadrons got their turn in the barrel with a “West Pac” deployment…aiding 7th Fleet forces in the South China Sea operation named “Market Time.” This operation was essentially an effort to blockade the vast South Vietnam coastline against North Vietnamese trawlers that could carry several tons of arms and ammunition in their hulls. P-3s were an essential airborne asset in this surveillance effort.

But it was now over and, after turning over Sangley Point duties to VP-22, the squadron’s crews and aircraft migrated back to Jax via Adak. Crew 20, the XO’s crew, was aboard LN-20. The XO and PPC, CDR Ralph Mason, straightened the nose, neutralized the rudder and expertly touched down just past the numbers. He could still feel the push of the crosswind on rollout as he smoothly pulled the power lever back over the ramp and into reverse. It was 1300 local time and they had 18 hours on deck before an early morning takeoff the next day.

The aircraft was parked and secured in accordance with SOP, including additional tie downs due to the consistent high winds in Adak. As the rest of the crew gathered up their stuff for a brief RON, the Flight Engineer remembered to check the local Maintenance Requirement Card. The MRC required that securing the aircraft in high winds included that the props be feathered and, to save battery charge, the power levers be pushed all the way forward (out of pitchlock reset range). Additionally, since the battery could be drained if someone later messed with the power levers, the Pitchlock Reset circuit breakers in the Flight Essential DC Bus had to be pulled. All that done, the crew headed for their respective quarters for check in and then to the clubs. Preflight was early the next morning.

0500 came early but, not being a tactical mission, preflight consisted of nav planning, fueling, filing and the FE’s getting the airplane ready. Since, in those days, P-3 squadrons had nine aircraft and twelve flight crews, there were extra passengers from other flight crews with Crew 20. LT Robert Hartl, a 26 year old 2P was the normal co-pilot for Crew 20, LTJG Randy Hotten was the 3P/Navigator. Since the XO was the senior officer of the three plane VP-45 group taking off that morning, LN-20 would be first to depart.

Sometime earlier, the FE’s had brought the props out of feather, removed the tie downs and placed the power levers in the correct position for engine start. The crew TACCO, LT Bill Dailey, briefed the nav route, reviewed safety procedures and assigned ditching stations to the extra passengers. The airplane had max passengers, a full bag of fuel, lots of WestPac “gee-dunk” and was heavy. The XO told his 3P, LTJG Randy Hotten, that he would be making the takeoff from the left seat and the flight station crew started the checklists. Engine start, receipt of updated weather and clearance went normally. LN-20 was cleared to taxi and was number ONE for takeoff.

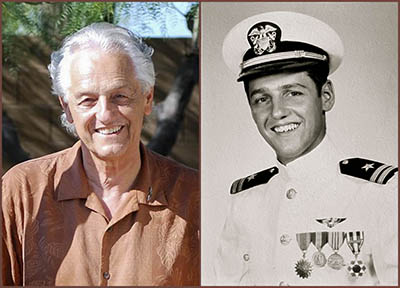

At 0800 local, weather was a broken layer at 1000’ with good visibility for takeoff; wind was out of the south at 15kts. LT Robert Hartl (pictured below right now and in 1968) recalls: “Looking out the window just before proceeding to my seat at the nav station, the sun’s first light was illuminating the hills.  Knowing this was the last leg in a six month deployment filled all of the crew’s minds and was reflected on all of our excited faces.” The TACCO ensured all crew, passengers and loose equipment were secured and, after strapping in himself, reported to the PPC that Condition FIVE was set for takeoff. Proceeding to runway 18, LN-20 was instructed by the tower to “position and hold” and one minute later was cleared for takeoff. The take-off checklist had been completed and all four power levers were advanced to takeoff power, brakes on….the aircraft shuttered and vibrated with the increasing engine RPM; 12,000 plus shaft horsepower came on line as the four big props bit into the morning air. Randy Hotten let go of the brakes and there followed a lurch and a roar as LN-20 began accelerating to a computed (heavy) takeoff speed of 140kts.

Knowing this was the last leg in a six month deployment filled all of the crew’s minds and was reflected on all of our excited faces.” The TACCO ensured all crew, passengers and loose equipment were secured and, after strapping in himself, reported to the PPC that Condition FIVE was set for takeoff. Proceeding to runway 18, LN-20 was instructed by the tower to “position and hold” and one minute later was cleared for takeoff. The take-off checklist had been completed and all four power levers were advanced to takeoff power, brakes on….the aircraft shuttered and vibrated with the increasing engine RPM; 12,000 plus shaft horsepower came on line as the four big props bit into the morning air. Randy Hotten let go of the brakes and there followed a lurch and a roar as LN-20 began accelerating to a computed (heavy) takeoff speed of 140kts.

In the flight station, young Randy Hotten kept the accelerating P-3 on centerline with a little nose wheel steering until the rudder became effective. The XO, acting as co-pilot, called the speed at 80kts, then “Refusal” and finally “Rotate” as the lumbering Orion reached takeoff speed. Just as Randy Hotten pulled the yoke back and felt the nose lift, there was, what was reported as, a “loud sound or explosion” followed by additional light and a rush of air in the flight station; all of which completely startled the cockpit crew. CDR Mason, in the right seat - an experienced pilot with over 6000 hours of flight time, verbally took control of the aircraft and, anticipating a serious aircraft failure, immediately elected to abort the takeoff. He grabbed the four big power levers and pulled them fully back, over the ramp and into reverse. Engine instruments indicated low fuel flow, low turbine inlet temp, zero shaft horsepower and near 100% RPM.

The four big props did not change pitch into reverse as the XO was expecting and the flight station crew thought the engines had mechanically decoupled from the props…the aircraft was not slowing and they were going to run out of runway. Both pilots went for full wheel braking but the aircraft was still just going too fast and, given its weight, was clearly going off the end of the runway and into the ocean. Shaft horsepower was now increasing and the XO realized his main priority now was to somehow stop the aircraft before it went into the water. He decided to take the aircraft off the left side of the runway and attempt to change the direction it was traveling away from the water. At some point, as the P-3 entered a low, ditch like, area, the nose yawed right, two big props bit into the dirt and the starboard wing was ripped away from the fuselage. The wing fuel tank ruptured and thousands of pounds of, now uncontained, JP-5 fuel burst into a huge orange and black fireball. Seconds before, as the aircraft left the runway the XO had called for all four engines to be “E-handled.” The Flight Engineer, already leaning forward as the aircraft decelerated, grabbed and pulled the E-handles for engines numbers 1 and 4. Since, by this time, the number four engine had departed along with the starboard wing, the #4 E-handle came all the way out past the FE’s right shoulder with about seven feet of cable attached.

There was still a tremendous amount of noise, and with the aircraft now successfully stopped, Randy Hotten looked up and realized that the overhead smoke removal hatch had blown open and the number two engine, just to his left, was still running at high RPM. The flight station pilots and FE, unstrapped and exited the aircraft via the cockpit escape hatch. Randy remembers: “The hatch was about 8 feet off the ground but the thought of being burned to death caused us to really hurry our exit. That resulted in our taking the most expedient of escapes – head first all the way down.”

Robert Hartl, the crew’s actual copilot was back in the “tube” through all this. He recollects:

“Takeoff roll and acceleration seemed pretty normal; at least as normal as it can be for a pilot whensitting in the back facing backwards. Suddenly, there was an unexpected loud noise from up forward, followed shortly by silence as the engines were transitioning from full forward thrust to reverse thrust. As I looked over my shoulder toward the cockpit I saw that our second flight engineer, “Frenchy” Lavigne, had unfastened his seat belt and was attempting to assist with the emergency. As suddenly as “Frenchy” got up, he just as suddenly whirled and returned to his ditching station, at the forward observer’s seat, wearing a terrified look on his face. I could feel the aircraft decelerate slightly and I fearfully sensed that the cockpit situation was deteriorating rapidly. Almost simultaneous with that thought, there was a severe lurching and bouncing of the aircraft and frightening bumping, scraping, pounding noises that lasted a number of very long seconds as the aircraft left the runway at about 120 miles per hour. My heart nearly stopped as I saw orange flashes of light illuminating the inside of the cabin. The flashing was caused by electrical sparks and fuel that had ignited into a tremendous fire as the right wing violently separated from the aircraft. Finally, all movement and unusual noise stopped and there was relative silence.

“My adrenaline was flowing as I spotted one of my fellow crew members running toward the port side over wing escape hatch. Thinking that this seemed like a marvelous idea, given the circumstances, my good friend, (TACCO) Bill Dailey, and I ran toward the same exit…We arrived in the opening simultaneously. As we attempted to squirm through the small exit I realized that one of us had to take a step back. The slapstick scene ended when I gave him a push out of the door onto the left wing. I then noticed that there was still a huge amount of noise and that was because the two engines on the remaining wing were still running at near full power. Bill was immediately blown off of the wing on to the ground. That suddenly seemed strange because, upon aborting the takeoff, the pilot should have put the engines in reverse and the props would have been “blowing” air to the front of the plane. Fortunately for us at that moment, the props were still in a forward thrust situation, as if they had pitchlocked before entering reverse pitch. Had the props actually been in reverse, we likely could have been sucked into the blades instead of being blown off of the wing. I followed Bill Dailey onto the wing and was likewise immediately blown aft to the tundra.

“I tried to stand up but was again immediately blown down on the ground by prop wash. My brain was having a hard time taking in all that surrounded me. A crashed aircraft, the pungent smell of both burning and raw JP- 5, the heat from the huge fire about 50 feet away, my worry about who had been killed or burned and the fact that I was still very much unhurt and alive. I crawled about twenty feet, until I could stand up and then ran about another seventy-five feet away from the airplane. I looked back and saw the huge furrow marks the wheels and landing gear had made in the ground. The aircraft was being consumed by flames as huge columns of black smoke rose up into the air. Fire trucks arrived in a short time and their crews spewed great streams of white foam on the flaming wreckage in front of our stunned faces. It seemed like it did not take too long to extinguish the fire.”

The guys from the flight station joined the rest of the crew a couple hundred feet from the wreckage and the TACCO did a head count. Amazingly, everybody was accounted for and no one was complaining of any injury. Considering the condition of the now smoldering LN-20, this seemed incredible. Crewmembers credited their PPC and XO, CDR Ralph Mason for his strictness in emergency drills, NATOPS study, general flight crew training and, specifically in this case, that all flight crew and passengers were strapped in with helmets on. The Adak tower dispatched a crew bus to the scene and the crew was whisked off to the hangar from which they had departed earlier.

Since LN-20 was the lead aircraft in the three ship takeoff, their fellow squadron mates had a ring side seat for the takeoff that ended in a ball of flame and disaster. Not sure how to proceed, both of these crews taxied back to the VP hangar, expecting to hear which of the crew had not survived. What followed were euphoric hugs and back slapping as the news of no injuries was passed about.

The crew aboard LN-20 that day remained in Adak for a number of days to assist investigators with the mishap investigation. Once released, Commander Patrol Wings Pacific directed that one of the Moffett Field based P-3 squadrons provide the aircraft necessary to ferry Crew 20 back to Jacksonville for a belated , but joyful, reunion with their families.

Author’s Second Note: As for me…well, I was just graduating from college and getting ready to finish my AOCS officer training when all this happened, but I do recall with great clarity that when I arrived at VP-45, 22 months later, I was assigned to Crew 20; and the LN-20 mishap (and particularly the pitchlock reset issue) were still hot topics. I spoke with retired CAPT Don “Cheeks” Hefkin (former RAG Skipper and VP Wing Commander) recently while writing this article. He told me that four years later (after this crash), when he was an instructor pilot at VP-31, lessons learned from this mishap were incorporated into the syllabus for pilots and FE’s - including NATOPS check rides. Specifically, by the time a pilot made PPC and a FE became a qualified FE, all had experienced the unexpected opening of the smoke removal hatch during take-off at a critical speed.

Also, though I attended the Navy’s Aviation Safety Officer School and was qualified at one time to investigate aircraft mishaps, my intent here was never to analyze cause factors, identify errors or assign blame. Besides, I did not have access to the formal mishap report. The story is just fascinating (at least to me) and I thought our members might find it interesting.

That said, the easy analysis of this mishap is that it started with a crew, unfamiliar with the blustery Adak environment, forgetting to reset a couple (pitchlock reset) circuit breakers. Yet this would never have been an issue or a problem on takeoff had the smoke removal hatch not deployed right at liftoff and the takeoff aborted. I believe what is important is that CDR Mason’s decisions and skill with the aircraft, after the abort, saved everyone’s life. That, perhaps, is what we should take away from this mishap…and 46 years later, is really all that matters.

Bob Hartl (the crew’s copilot who was in the Nav seat) provided a great deal of the information for this story. He went on to fly and captain Delta Airlines commercial aircraft for many years. He now lives in Scottsdale, Arizona and is a sculpture artist. After a full career in the Navy, CAPT Randy Hotten (who made the takeoff) lives in Belleville, Michigan and is a Life member of our Association. Randy provided background details and most of the post mishap photos for this article.

For those who have additional interest in the Pitchlock and Pitchlock Reset functions of the T-56 engine, see the following article just below.

The T-56 Engine and Pitchlock

By: Bill Hobgood

The P-3’s T-56 turbo-prop engine essentially turns that huge propeller at a constant 100% RPM.

During flight, moving the cockpit power levers forward or back, to increase or decrease the aircraft’s speed or altitude, does not change propeller RPM, it changes the pitch (blade angle) of the propeller blades. A “prop governor” hydraulic system is what maintains the propeller at a constant 100% RPM at any power (lever) setting in the normal operating (flying) range.

There are some conditions, like failure of the prop governor just mentioned, that might cause the propeller to overspeed past 100% RPM. Propeller overspeed is NOT a good thing. If a prop starts to overspeed, when it reaches 103.5% RPM, a gearing system will engage and LOCK the propeller at whatever pitch it was. It is now a “fixed pitch” prop… because the propeller has been pitchlocked!

So, pitchlock is a safety feature that jumps in and mechanically locks the prop at the then current blade angle/pitch, in order to prevent further propeller overspeed.

But….the pitchlock system, even as a safety feature, can be a problem. Shortly after landing, the pilot pulls back the power levers “over the ramp” and into reverse; NOW the fuel control system (instead of the hydraulic prop governor) controls prop blade angle. Unfortunately, the fuel control system is a little sloppy in controlling RPM. That sloppiness requires a separate electrical system called “Pitchlock RESET.”

Pitchlock RESET goes into play only when the power levers are pulled “back to and beyond the ramp” – like in the landing situation just mentioned. In this condition, the prop is “allowed to overspeed” up to around 109% unimpeded. So all this pitchlock reset system does is allow some degree of additional prop RPM (109% instead of 103.5%) before pitchlock will occur. However, since pitchlock RESET was not available to LN-20 (the circuit breakers were never pushed in), the engines pitch locked at a positive blade angle and no reverse thrust was avail to help stop the aircraft.

WebMaster's Note: In July of 2020, during the 5th month of the Coronavirus outbreak, CAPT Randy Hotten (left seat pilot in the story above) provided me a written, personal account of his recollection of the LN-20 crash. His story follows.

LN-20 Takeoff Mishap, Adak, 1969. By Randy Hotten

06-02-1969, Adak, Alaska time zone 0600. We were going to be back in the states today, one more night and I would be home my wife in her eighth month of pregnancy with our son. We had been flying around Vietnam for six months, this was out last stop before returning to the states. Vietnam was behind us, for the first time in months we were under max gross weight and we had full power available. What could go wrong? How about a wing breaking off a P-3 on takeoff and escaping from a burning wreck at the end of the runway?

I was in the left seat for the takeoff, in the Navy we never made a right seat takeoff or landing until we were designated an instructor pilot. Even though I only had about 1,000 hours total time, I had nearly 400 hours of pilot time in the last six months and was very comfortable in the left seat. This was a piece of cake take off. Light weight, full power available. At rotate as I pulled the nose up to take off attitude the smoke hatch in the cockpit popped open, and the PPC in the right seat took control of the airplane and aborted the takeoff. He had been at Test Pilot School and did the fleet acceptance on the P-3 and knew it would operate outside of the envelope, and he wanted to demonstrate this capability. The props failed to go into reverse because the FE had left the Pitchlock Reset CB’s out. As this was going on the FE reached down under his seat and reset the CB’s, but it was too late. The CB’s had been pulled the night before as a procedure found on a MRC Maintenance Required Card. In high wing conditions you feathered the props and pulled the Pitch Lock Reset CB’s to prevent running the battery down. Props feather, power levers in the ground range, arms the Pitchlock reset system, it is on the Hot Battery Bus. The Pitchlock reset system allows the engine to monetarily overspeed while going into reverse and not go into Pitchlock. With those CB’s out there is no reverse thrust and the props are stuck in forward thrust there was no way to stop the airplane. Compounding this because of the Pitchlock angle and the power lever position we got low HP, low TIT, 100% RPM, and low Fuel Flow, classic decouple indication, so we tried to stop with brakes, blew out the tires and failed to stop, because we were locked in forward thrust. As we slowed down HP increased.

So the PPC took it off the left side of the runway in a severe right yaw. The PPC called for E-handle #1 and #4, the FE, Lorenz pulled the handles, as this was going on I was overcome with the feeling of the “Peace of God that passes all understanding” “This is not fair, I have done my time in Vietnam, I am supposed to home tomorrow, I have a wife and child on the way, why me, why now”. My mind was racing. I picked up the mike on PA and said, “This is not a drill prepare to ditch, prepare to ditch”. When the right wing struck the ditch at the side of the runway the mike flew out of my hand as the right wing separated from the fuselage and turned into a giant ball of fire.

So the PPC took it off the left side of the runway in a severe right yaw. The PPC called for E-handle #1 and #4, the FE, Lorenz pulled the handles, as this was going on I was overcome with the feeling of the “Peace of God that passes all understanding” “This is not fair, I have done my time in Vietnam, I am supposed to home tomorrow, I have a wife and child on the way, why me, why now”. My mind was racing. I picked up the mike on PA and said, “This is not a drill prepare to ditch, prepare to ditch”. When the right wing struck the ditch at the side of the runway the mike flew out of my hand as the right wing separated from the fuselage and turned into a giant ball of fire.

As we were going through the ditch checklist, the PPC called for E-Handle #2 and #3, I remember the FE pulling the E-Handle and seeing the #3 E-Handle in the FE’s hand pointing at the ceiling with a long cable going back into the top of the instrument panel. The ring wing was no longer attached to the airplane and the cable went nowhere. The airplane came out of the far side of the fire about 75’ away from the right wing. The cockpit was filling with smoke and the fire was right outside the windshield making it difficult to figure out where was the fire. There were 21 on board, we were all out in 15 seconds.

The deceleration forces were so severe when the wing broke off that I had bruises on my chest where the shoulder harness came across chest. It was like someone had painted the straps on my chest, you could even see the imprint of the adjustment buckles. I was in a panic to get out of the cockpit which I thought was on fire. I leaped out of my seat and walked across the fuel panel to get to the emergency exit in the cockpit. But I could not get out of my seat, my mind is racing “What the Fuck is Going on?”. “Is this a dream, what is going on” But my mind went back to my Dilbert Ducker training from two years ago at AOCS. “If you are tapped go back to your last position and check that everything is free”. So, I sat down again and found out my flotation vest strap had hooked on the arm rest and that is what was holding me back. I undid the armrest and was the first person out of the cockpit. The exit was about ten feet off the ground, like jumping headfirst out of a second story window, but away I went. It was a good thing I was delayed going out the exit, because when the airplane came to a stop the #2 engine was still running and its prop spinning right outside of the exit. Because the #3 E-Handle had broken off and the FE never finished pulling out the #2 E-Handle. The PPC pulled the #2 E-Handle to shut down the engine. Crew members going out the port over wing exit said they were blown off the wing by the #2 engine that was still running. I was 24 at the time and indestructible.

The deceleration forces were so severe when the wing broke off that I had bruises on my chest where the shoulder harness came across chest. It was like someone had painted the straps on my chest, you could even see the imprint of the adjustment buckles. I was in a panic to get out of the cockpit which I thought was on fire. I leaped out of my seat and walked across the fuel panel to get to the emergency exit in the cockpit. But I could not get out of my seat, my mind is racing “What the Fuck is Going on?”. “Is this a dream, what is going on” But my mind went back to my Dilbert Ducker training from two years ago at AOCS. “If you are tapped go back to your last position and check that everything is free”. So, I sat down again and found out my flotation vest strap had hooked on the arm rest and that is what was holding me back. I undid the armrest and was the first person out of the cockpit. The exit was about ten feet off the ground, like jumping headfirst out of a second story window, but away I went. It was a good thing I was delayed going out the exit, because when the airplane came to a stop the #2 engine was still running and its prop spinning right outside of the exit. Because the #3 E-Handle had broken off and the FE never finished pulling out the #2 E-Handle. The PPC pulled the #2 E-Handle to shut down the engine. Crew members going out the port over wing exit said they were blown off the wing by the #2 engine that was still running. I was 24 at the time and indestructible.

As we stood there watching the burning airplane, a school bus stopped, and asked if we wanted a ride back to Base Ops, thinking it has been sent to pick us up, we climb on the bus. Small world incident, the driver of the bus was my cousin, Uncle Bob’s adopted son, we had not seen each other in years. Well it turns out the bus had not been sent by Base Ops; it was just making a routine run back from a school on the base. So, when the crash crew showed up, they could not find any of the crew. This was a real worry for the crash crew.

As we stood there watching the burning airplane, a school bus stopped, and asked if we wanted a ride back to Base Ops, thinking it has been sent to pick us up, we climb on the bus. Small world incident, the driver of the bus was my cousin, Uncle Bob’s adopted son, we had not seen each other in years. Well it turns out the bus had not been sent by Base Ops; it was just making a routine run back from a school on the base. So, when the crash crew showed up, they could not find any of the crew. This was a real worry for the crash crew.

Lou, my wife, had been having dreams about the squadron returning. The squadron would show up and I would not be there. She was worried about me not coming home. She gets a phone call from the squadron. The person calling says “Your husband’s airplane has crashed in Alaska, and he will not be coming home”. She never heard the words “he is alright and will be calling you later”. In her mind her worse fears had been realized, she was pregnant, and her baby would never know its father. When I called later that day, she was all tears, and I tried to console her that I was all right and would be home soon.

The strange thing was I had been having takeoff crash dreams about once month. I attributed this too always being at max gross take off weigh or over and being temperature limited on horsepower. I stayed in Adak five days for the accident investigation and we were then flown to NAS Moffet Field on a P-3 belonging to VP-47, the deployed squadron. All white knuckles on that take off sitting in the galley seat in the back of the airplane with Bob Hartl. We RONed as NAS Moffet and VP-5 picked us up on June 8 and took us home. Being a nervous flyer now I was incensed when at FL270, the PPC elected to turn on the water injection to climb to FL290, he turns it on and all four TIT overtempt lights come on. My mind is going “Good Grief, I am about to witness a four-engine flame out at FL270 and end up crashing in a Nevada dessert”. But we got home and there was Lou. I was never so happy in my live to see someone as seeing her that day, six months of her burden of having a loved one in a

combat zone was over, I was safely home. I am so fortunate to have her in my life.

Send questions, comments or suggestions regarding this website to: vp45assoc@vp45association.org

Copyright © 2005 PATRON FOUR FIVE ASSOCIATION